I see a lot of “after” photos online and while they look great, some of them even remarkable, I know from experience that what you see in a photo does not represent the whole of a project. With the right tools and photographer, it’s easy to take a great photo — the right lighting, great camera equipment, and, when all else fails, some Photoshop artistry can easily gloss over some significant flaws in design and fabrication. These slick shots can easily impress a builder, designer or architect seeking the right look for their project. And while I see these beautiful portfolio shots on social media and websites everywhere, it’s surprising how often I hear from a builder or architect that they need us to take over that exact job because the fabricator failed to deliver what was promised. So how do you prevent project catastrophes like this? How do you know that the fabricator you choose can handle the work you require? How do you dig deeper into a portfolio of work to get the story that the pictures don’t tell?

Evaluating Your Vendor

Whether it be commercial or residential, these are the questions I suggest you ask your fabricator (metal, wood, or otherwise) before you select them for a project. Asking these questions will help you assess their capabilities and make sure they are a fit for your project and needs. Most fabricators don’t volunteer this information because they’d rather not answer the tougher business questions, especially if the answers might not paint them in a good light. A good vendor should be open to discussing their experiences and capabilities openly and honestly, even if the answers mean not getting the job. Nothing ensures certain disaster more than taking on a project that’s beyond your company’s scope. In assessing your current vendors, ask yourself:

- Do you frequently have to hand-hold the fabricator through a project? Assess why. What skill sets or details are they missing?

- Did you “inherit” a fabricator from someone else on the project or from a past experience that seems to be in over their head on this project?

- Do you regularly have to call in other vendors or team members to help because your fabricator lacks skill sets or resources required?

- If the person creating your project drawings is not experienced in the material being used, does the project require an expert in that material for the project to meet your goals for design, stability or performance?

In evaluating a new fabricator, ask them:

- Can you show detailed photos of your work?

- Don’t just depend on the portfolio shot. Ask to see up-close photos of their work where it counts.

- Do they take the time to ensure clean lines and edges? Is the work structurally sound?

- What details does your project/client need? Can they show examples of that?

- What is their team capability?

- How many people do they have on their team and who will be assigned to your project? Get the backgrounds, experience and skill sets of all team members. What do they bring to your project specifically?

- What is their dedication to the company/brand reputation? Are they freelance contractors unattached to the company they are working for, or dedicated employees with the same level of commitment to quality and endurance?

- Can they work together as a unit? A unified team can manage a change order handoff seamlessly together or address unforeseen issues quickly and professionally. Will they be able to adapt as you need without problems arising?

- What is the flexibility of the team to manage additional work and change orders?

- Do they have the skill sets?

- Do they have the manpower?

- What is their experience in dealing with changes and how does that impact the project?

In evaluating any fabricator, assess for yourself:

- What is the cost of delay for your project with their team?

- Commercial projects often have a hard cost on delays because unfinished projects limit the use of a facility.

- For residential projects there are cascading issues of accommodating other vendors as well as the owner’s needs and expectations.

- What guarantees does your fabricator provide to keep to deadline?

- What is the stability of business:

- Do they manage funds well? Will they be in business a year from now? If they are not financially stable, can they handle economic instability if markets shift that could affect your work?

- Do they have a stable list of vendors that they have good relationships with who can provide references? Vendor relationships are an indication of financial and managerial stability. Good management will have long term relationships.

This may seem like a lot to ask of a vendor, but considering the investment of time and resources that you make in a project, or perhaps multiple projects, it’s well worth the time and effort to delve into these questions before committing to a vendor or continuing to assign projects to a current one.

Real World Example #1 — Operating Under a Tight Deadline

This project not only required a variety of skill sets, but also needed to be completed in a tight, 3-month time frame. A one-person or small shop would have had a hard time running this project and managing other projects at the same time. While this was a quick project for Modern Metal Solutions, it would’ve been all-consuming and even overwhelming for a smaller shop, which would have resulted in missing critical dates.

Real World Example #2 — Finding the Right Skill Sets

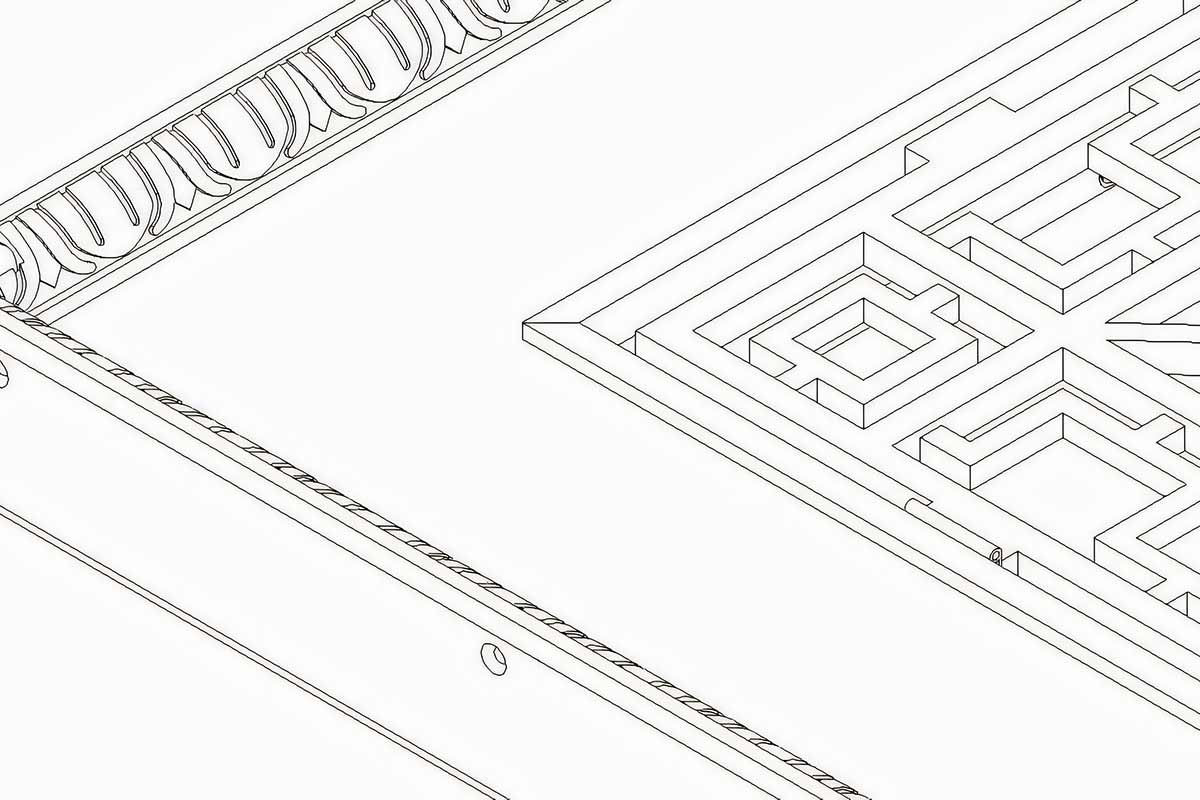

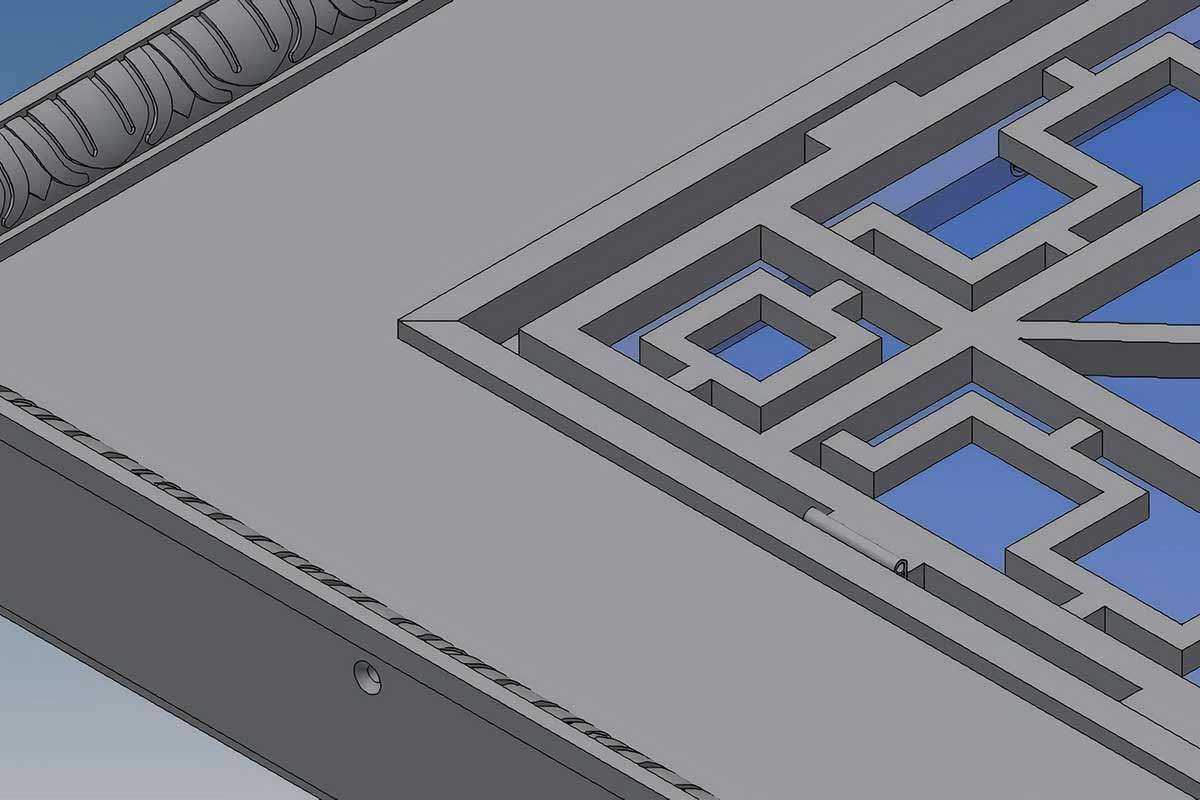

For many projects shop drawings are needed to specify project details. Without the right CAD skills available in-house, the drawings you receive might not be very useful and may even need to be completely re-created, costing you time and budget from the project. When evaluating your vendors, be sure they have the skill sets your project needs, or be prepared to fill those gaps.

Do Your Homework

You invest a lot in your projects. Take the time to do a deeper dive into the background, skill set and work ethics of the vendors you assemble for your project teams. In the end, it’ll save you valuable time and money, not to mention frustration, while ensuring the end result is the quality you deserve in the time frame you were promised.